Altrock Is Staking Its Claim in the Terrazzo Trend Using Reclaimed Byproducts

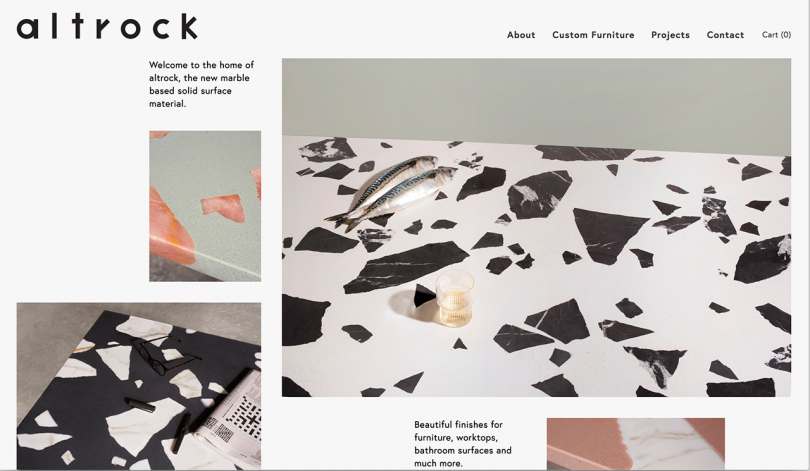

As soon as Altrock came to our attention, a solid surface material brand using reclaimed byproducts from the natural stone industries, we had to know more. This new marble-based material – a contemporary take on terrazzo – offers up beautiful finishes for furniture, worktops, bathroom surfaces, and so much more, with the same hard-wearing surface you would find in the original. To learn more about UK-based Altrock we spoke with Robin Grasby, and picked his brain on the material’s inception, what it took to arrive at this point, and just how Squarespace’s all-in-one website building platform helped out.

Robin started out by sharing, “I trained as a cabinet maker and joiner as a teenager, then went on to do my BA in furniture design. I’ve always enjoyed keeping a breadth of variety in the kinds of projects I get involved in, and prior to launching altrock at the end of last year my practice covered bespoke furniture and interior fit outs spanning several sectors. I’ve designed and fabricated, from kitchens and restaurant furniture to house boat and office interiors. I’ve always been too curious to stick to the material discipline I was trained in and have tried my hand at any new process I can, always looking to see how I can experiment and bring new materials and finishes into projects wherever the briefs may allow.”

“It was through a couple of projects back in 2017 that I originally began playing around with concrete and natural stone. These experiments, along with some experience in resin work and casting from a couple of years spent as an art fabricator, informed and ultimately led to the development of Altrock. The initial feedback I was getting for the first few pieces was really exciting, and as the current terrazzo revival was really kicking into gear I decided to redirect my practice to focus entirely on Altrock. Currently it’s just two of us full-time, but the team expands with freelance makers when we have big jobs to take on.”

Recent shifting trends have watched solid marble eclipse terrazzo as the decorative building material of choice. With its return to prominence, and featuring the qualities of being hard-wearing, cost-effective, aesthetically uncompromised, and sustainable, it makes for a great alternative to solid stone. The only problem is that in the UK there aren’t many remaining terrazzo manufacturers – and that’s where Altrock comes in.

“Through working with one of the only suppliers left in the UK, I found that the flexibility of process and eye for trending aesthetics was not there, it was a ‘stuck in their ways’ sort of thing. So I started developing a casting process on my own. There were several stages to the development, all involving a whole new realm of research. I had a few experts to call on for their extremely technical insight, especially resins and silicons used for casting. Ultimately though, the process is a simple one – and it had to be for me to begin with. Every step of the development was about honing the process to use readily-available materials, and the least machining possible. There wasn’t the money to invest in new machinery, and I didn’t have the space for it! These limitations guided the development of Altrock to make it a simple, low waste, fast to produce material, that used a high proportion of waste materials in its make up,” Robin explained.

The manufacturing of Altrock begins by combining recycled marble flour, recycled marble chips, and chunks of offcuts and broken pieces from beautiful marble slabs. All of these are byproducts of local marble manufacturing, waste materials from the production of various luxury products and building finishes. The marble is mixed and bonded with a small amount of resin, pigmented in a huge range of custom colors, and cast by hand in slabs of all shapes and sizes. Altrock is sealed with wax oil that dries to a matte finish, deepening and highlighting the veining of the natural stone pieces as well as providing a durable, waterproof, and stain resistant finish. The material can be made in a wide range of color ways, including background colors and a wide variety of natural stones.

Having created a unique solid surface product with so much variability, we had to know Robin’s personal favorite way of using Altrock and whether she has it in her home. “Earlier this year I developed a method for cutting and joining slabs of Altrock to build seamless, strong, three dimensional shapes. There are a lot of exciting possibilities for this, and I designed a collection of furniture pieces to showcase the potential for this method. Lots of these pieces are doing the rounds being shot for various press pieces at the moment, but I do have my eye on the little coffee table for my own flat,” he said.

Having had the chance to know the product so well, it’s no surprise that Wallpaper* magazine commissioned Robin to produce pieces for the Wallpaper Handmade Show at the Salone in Milan in early 2019.

“They sent me out to a quarry in Turkey who we teamed up with, using their beautiful and unusual stone in these one-off pieces. This trip reawakened the six year old in me, obsessed with diggers and other massive machinery. The scale of the operation there is mind-blowing, and the scenery at these quarries is utterly alien. Walking around in the bright white mud overshadowed by 20 meter vertical walls of fresh cut marble was an incredibly visceral experience. It was fascinating to get such an in-depth understanding of both the processing of this incredible material, and its physical origins as well.”

“It turned out that the aphrodite marble came from a very special corner of a quarry, where a normally grey and white stone has been infiltrated by an unusual mineral deposit. Over millions of years of heat and pressure, this deposit has manifested as streaks of stunning bright pinks throughout the grey rock. This rich veining and colour variation made aphrodite an unbelievably good stone for some very special edition pieces of Altrock,” Robin shared. Her hope is that Altrock will get more into designing and producing more special edition pieces in the future.

At the end of the day, Altrock is a budding product brand with lots of potential. But there are many business tasks, aside from product testing and designing, that you don’t want slipping off your radar. Robin tapped Squarespace and their all-in-one business platform to keep Altrock rolling right.

“Squarespace has been priceless for Altrock. As I said, there was no initial investment to start the brand. It all grew from the work I was already doing as a furniture maker, so I had to do everything myself: branding, copywriting, art directing the first product shots, and of course building the website. The only other person I was paying was my accountant, as that bit terrifies me the most. The template system of Squarespace is key to being able to build something great looking with no understanding of web design. It takes a bit of time to understand the language, geography of your site, and how its constructed, but once you crack that the tools at your disposal are really intuitive and powerful. My sister is a very talented graphic designer, so I had her to bounce ideas off and keep me on track. But the templates work really well in restraining you just enough to keep the design controlled and precise,” Robin detailed.

Ready to get to work on your own site? Take the first step with a Squarespace website. Use coupon code DESIGNMILK at checkout to get 10% off your first purchase.

from Design MilkInterior Design – Design Milk https://ift.tt/2XpNhtL

via Design Milk

No comments